Welcome to the official website YUSH Electronic Technology Co.,Ltd

Find quality Depaneling Manufacturers_v-cut Machine Suppliers _PCB cutting machine Exporters_PCB Router Importers_pcb cutting machine Wholesalers

| Machine Performance | |

| Repeat Position Accuracy | ±0.01mm |

| Print Accuracy | ±0.025mm |

| NCP-CT | 7.5s |

| HCP-CT | 19s/pcs |

| Process CT | 5min |

| Transfer line CT | 3min |

| Substrate processing parameter | |

| Max9∶27imum board size | 400*340mm Scalable:530*340mm(Options) |

| Minimum board size | 50*50mm |

| Board thickness | 0.4-6mm |

| Camera Mechanical range | 528*340mm |

| Maximum board weight | 3kg |

| Board edge clearance | 2.5mm |

| Board height | 15mm |

| Transport speed | 900±40mm |

| (Max)Transport speed | Segment control 1500mm/s(Max) |

| Transport direction | One-section transport rail |

| Transmission direction | Left to right |

| Right to Left | |

| In and out the same | |

| Support System | Magnetic Pin |

| Support Block | |

| Manual Up-down table | |

| Board clamp | Automatic top clamping |

| Side clamping | |

| Adsorption function | |

| Printing Parameters | |

| Print Speed | 10~200mm/sec |

| Print Pressure | 0.5~10Kg |

| Print Mode | Single or double doctor blade printing |

| Queegee Type | (09/s5/st alfue) apels apels ofoonbs/mand (09/ss/stalle) Chiell/Dievilievi |

| Snap-off | 0~20mm |

| Snap-Speed | 0~20mm/sec |

| The template frame size | 470*370mm~737*737mm(Thickness∶20-40mm) |

| Steel mesh positioning method | Automatic Y-direction positioning (compatible with manual compensation adjustment) |

| Cleaning Parameters | |

| Cleaning System | Dry, Wet Vacuum three modes |

| Cleaning system | Up Drip type |

| Cleaning stroke | Automatic generation |

| Cleaning position | Post cleaning |

| Cleaning Speed | 10-200mm/sec |

| Cleaning fluid consumption | Auto & Manually adjustable |

| Cleaning paper consumption | Auto & Manually adjustable |

| Vision Parameters | |

| CCD FOV | 10*8mm |

| Camera type | 130 Thousand CCD Digital camera |

| Camera System | Lock up/down optics structure |

| Camera Cycle time | 300ms |

| Fiducial mark types | Standard Fiducial Mark Shape |

| Round,square,diamond,cross | |

| Pad and profile | |

| Mark size | 0.5-5mm |

| Mark number | Max:4pcs |

| Stay away number | Max: 1pcs |

| Smart equipment | |

| safely control | Door open to stop, abnormal alarm |

| 2D inspection | Detection of less tin/missing print/continuous tin |

| Automatic crimping | Automatically push up the guide rail |

| Vacuum adsorption | Platform vacuum adsorption |

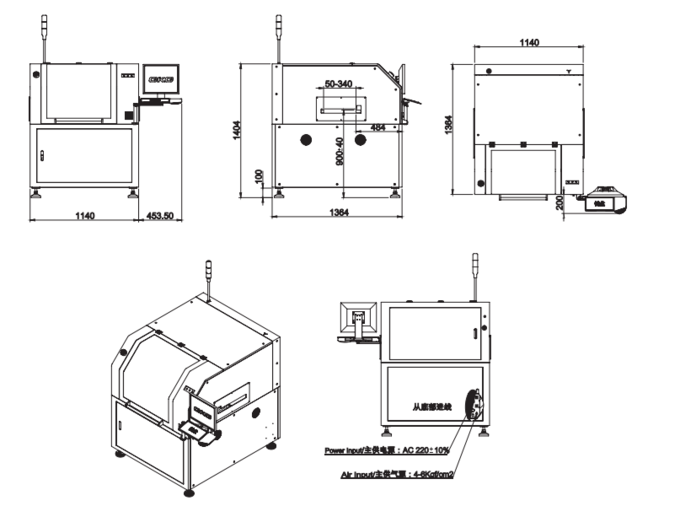

| Machine parameter | |

| Power Source | AC:220±10%,50/60Hz2.2KW |

| Air Pressure | 4~6Kgf/cm² |

| Air Consumption | About 5L/min |

| Operating Temperature | -20℃~+45℃ |

| Working environment humidity | 30%~60% |

| Machine dimension (without Tower light) | 1404(H)mm |

| Machine Length | 1140(L)mm |

| Machine Width | 1364(W)mm |

| Machine Weight Approx | Approx∶About900Kg |

| Equipment load bearing requirements | 650Kg/㎡ |