In-line vertical reflow oven, with compact structure, small space occupying which greatly saves building space; high production efficiency which is much higher than the traditional oven, especially for the products which needs long time heating in the oven and it effectively improves the production capacity. The demand for the vertical reflow oven is larger and larger; the vertical type instead of the traditional curing oven has become a trend.

Advantages:

1.Effectively improve the capacity

2.Enhance the curing quality

3.Small occupying area and save the workshop space

4.Lower the use-cost

| S SERIES Specification | ||||

| Model | YSL-200S | YSL-300S | YSL-400S | Remarks |

| Machine Dimension | L2140xW1800xH2150mm | L2390xW1870xH2150mm | L2870xW2010xH2150mm | |

| Machine Weight | Approx.1600kg | Approx.1800kg | Approx.2000kg | |

| Product size | MAX:W250*L320mm | MAX:W320*L410mm | MAX:W460*L530mm | |

| Inlet height | 900±20mm | |||

| Storage type | Vertical storage | |||

| Storage quantity | Max product storage number:60pcs | Can be customized | ||

| Pitch height | Integral multiple of 25.4mm | Can be customized | ||

| Temperature range | Room temp~200℃ | |||

| Warming up time | Approx.15min | Set temp 150℃ | ||

| Running power | About 6KW | |||

| Total power | 45KW | |||

| Temperature control accuracy | ±1℃ | |||

| Abnormal alarm | 3-color signal lamp + Human-machine interface prompt | |||

| Power supply | 3P5L 380V 50/60Hz | |||

Double lifting system, great quantity of storage space,can meet the high efficiency production

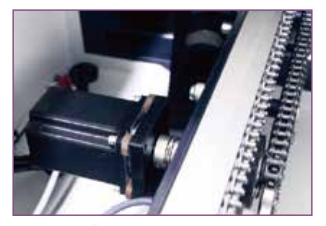

Adopts high accuracy step motor for buffer and push structure, ensure the pushing accuracy

PCB conveying detection in the oven adopts imported fiber optic sensor which greatly ensure the operation reliability.

Main application: Chip bonding, under fill, components packing and other production process which needs thermo curing. (Include automobile, motor, instrument, communication and other industries)