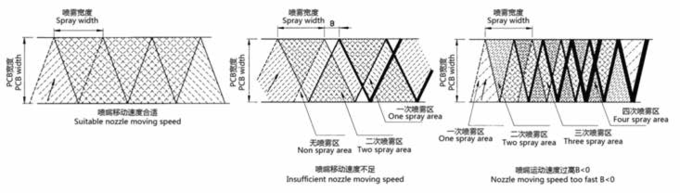

One.Use of spray nozzle and vertical position of the PCB spray soldering flux will improving uniformity and penetrability.

The vertical PCB board spray(with path optimization system)

A.Use of spray nozzle and vertical positioning will allow the soldering flux on the PCB to be more evenly spread, better wetting performance of the holes and improve the adhesiveness of the solder metal.

Traditional Soldering Flux Method New Soldering Flux Method

B.Path optimization system guarantee the flux coating uniformity when sprayed the second time.

C.Advanced software system, PCB will be auto-adjusted according to the speed of transportation.

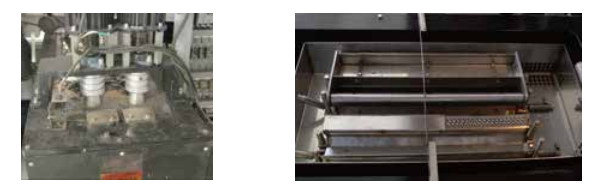

Two.Use of cast iron solder container with ceramic coatiing can increase the life span of solder container.

New antl-corrosion cast Iron solder pot.

The corrosion behavior of lead-free wave solder pot materials research (Harbin Institute of Technology 2006 Master candidate research topics),

| Solder Container size | Solder Container thickness | Life(years) 8 hours/1 day | |

| 316 Stainless steel | 1165×480×265mm | 3mm | ≥1 |

| Titanium | 3mm | ≥5 | |

| Heat Resistant cast iron | 10mm | ≥8 |

1. Cast iron solder container. 2. 5 years replacement,

1. Cast iron solder container. 2. 5 years replacement,

1.The cast iron wall thickness of 10mm pot resist deformation under heat.

2.Cast iron contains large quantities of graphite and it has low humidity so reduces the effect of corrosion. The ceramic coating improves corrosion resistance and surface smoothness, hence; increase the service life of the solder pot.

Three.Devices using new channel and nozzle reduce tlhe amount of oxidation hence effectively cutting operating cost.

Lowering oxide slag device.

Lead-free wave solder oxide slag formation characteristics and improve process measures (Harbin institute of Technology 2007 Master candidate research topics)

Inflential factors for oxidafion level:

Solder oxidation can be caused by many different factors, some are uncontrollable such as high temperature from soldering. Other factors can be controlled using mechanical measures such as flow rate, drop, cross section, spray of flux etc.

Amount of Oxidation=f(amount of drop,contact area, coefficient of velocity, temperature coefficient)variable quantity: amount of drop, velocity, contact area Fixed quantity: soldering temperature:

Specific measures to reduce oxidation.

1. By controlling the flow rate of the peak, reducing the drop,limiting contact area and shortening the path of movement, we can effectively reduce the oxidation and eliminate the amount of creases produced. We can prevent the generation of black oxide by using dynamic rotation to isolate oxygen.

2. Adjust the width of the nozzle according to the width of the PCB hence effectively reducing the solder oxidation.

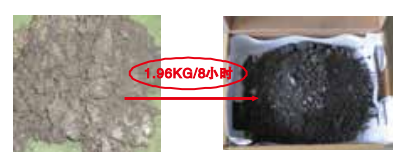

Oxidation residue test report.

Testing Criteria∶

Simulate normal plate production process

Tin furnace temperature:260℃

Peak width: 400mm

Wave height: 8mm

Testing time: 8h

Leading the industry with low operating cost as supplier of wave soldering equipment.

| China | Overseas | |||

| Model | Suneast | China brand | Famous American brand | Famous Germany brand |

| Wave width(mm) | 400 | 400 | 600 | 500 |

| Dross quantity kg/8h | <2 | 4 | 8 | 8 |

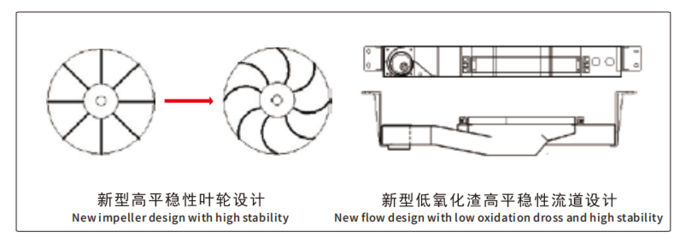

Four.Use of new impeller and passage design increase the smoothness of the peak.

Technology for controlling the smoothness of the peak.

A.The nozzle, passage way and impeller structure all directly affect the smoothness of the peak.

B. The smoothness of the peak can be controlled within 0.5mm.

Note:Germany wave soldering performance tester actual measured value is within 0.2mm.

User friendly Software Design.

1.Good demonstrative chart as interface making it easy to operate;

2.Additional SPC query function result in a more efficient control of the production process and guarantee a more stable performance.

3.Includes trouble shooting information, common problems and solutions in software which helps reduce training cost.

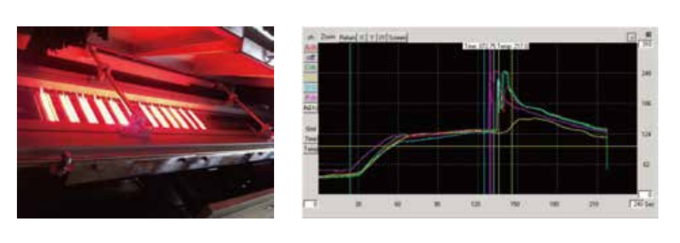

The advantage of mixed preheat.

1.IR preheating can raise temperature fast and hot air preheating can increase temperature uniformity.

2.Mix IR preheating and hot air preheating cannot only raise temp.quickly but also enhance temp uniformity.

3.Mixed preheating goes especially well with water-solulde flux.

Built-in partial selective spraying device.

1.Stepper motor moves in the direction of X ard Y axis to achieve partial selective flux spraying.

through synchronous belt,ball screw and linear guide rail.

2.Excellent spray nozzle can realize spot-spray,line-spray and rectangle-spray.

3.Controlled by PC+ motion control board,quick respond,high accuracy,programmable and user friendly Ul. 4.Suitable when spraying area is under 50% of total area,which can save flux by over 50%.

Partial Nitrogen-charging device of solder pot.

1.The partial nitrogen releasing unit can minimal amount of nitrogen to create high concentration of nitrogen around the wave.

2.The use of stainless steel nano-porous tube release the nitrogen uniformly and in high concentration

3.The 3 flow meters control the 3 nitrogen tubes with consumption rate at 15m3/h and the concentration of nitrogen around the nozzle is about 1000ppm.

4.Do not support online detection of nitrogen concentration.