Scope of application:

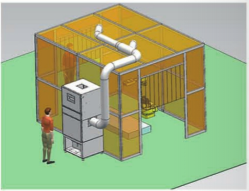

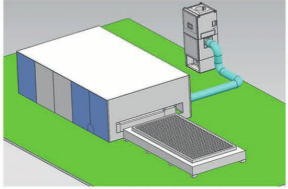

welding robot workstation smoke and dust control, laser cutting, drilling, sandblasting, powder spraying, engraving, grinding and polishing, stirring, powder feeding, powder bagging, powder screening, laboratories, etc. It can be placed indoors or outdoors to collect and control floating, suspended dust and smoke, and it can be centralized for single-post or multi-post dust removal.

Main feature:

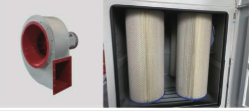

1. Adopt centrifugal fan and modular design, with large air volume, low noise and stable performance.

2. Schneider brand electrical appliances to improve product safety and stability.

3. Equipped with 4 Aoslon nano flame retardant material filter cartridges, the filtration area is 66 square meters.

4. The pulse cleaning control system can set the pulse cleaning interval according to the working conditions.

5. Standard remote/local switch function, which can be linked with production equipment.

Centrifugal fan / 4 Aoslon nano flame retardant filter cartridges 66 square meters

Schneider Electric / dust box

| Technical Data | Unit | YSL-550P | YSL-750P |

| Power | Kw | 5.5 | 7.5 |

| Voltage | V-Hz | 380-50/60 | 380-50/60 |

| Container capacity | L | 50 | 50 |

| Filter area | ㎡ | 66 | 66 |

| Filtering accuracy | μm | 0.3 | 0.3 |

| Qty of filters | PC | 4 | 4 |

| Airflow | m³/h | 3300-5000 | 4300-6300 |

| Vacuum | Kpa | 2.6-1.8 | 3.03-2.2 |

| Noise level | dB | 70 | 72 |

| Inlet diameter | mm | 250/300 | 250/300 |

| Cable length | m | 8 | 8 |

| Product size | mm | 900*950*2420 | 900*950*2420 |

| Filter cleaning method | - | Pulse cleaning | Pulse cleaning |

| Switch control mode | - | Local control +Remote control | |